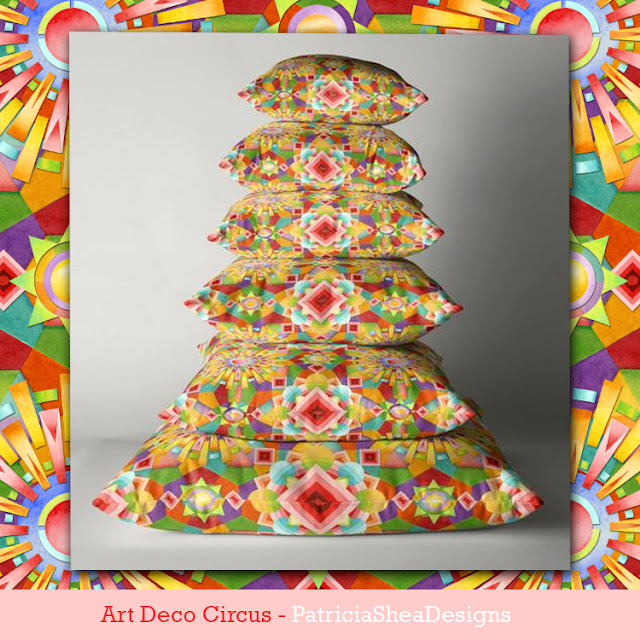

Sell/Produce/Deliver: digital printing “made to order” products

My business model explained

A new world (or “paradigm”) is opening up for digital designers and independent artists. Best thing? It’s much more agile and environmentally sustainable than it ever was before under the traditional model. Designers only need their time and talents, upload their prints on the online venues to Sell / Produce / Deliver under demand. A big achievement is that no unsold inventory is contributing to landfill while using the digital printing formula. Digital designers will save a massive amount of water, energy and toxic dyestuffs. A much brighter future in slow fashion comparing digital printing vs analogue printing. Learn all about the useful and achievable methods, processes and techniques of ourgoodBlogger & digital designer Patricia Shea first hand! What are you waiting to build your ethical empire?

A new paradigm paradigm.

So why double paradigm? “Paradigm – a typical example or pattern of something”. As a professional surface designer, I create patterns. And there’s a big and most wondrous shift in the way patterns are now being printed digitally. It's become much more agile, environmentally sustainable and, for me, fun and a dream come true. I am thrilled to see my carbon footprint diminish via the amazing auspices of digital printing and print on demand, as I have endeavoured most of my adult life to be as eco-conscious as possible. Now I am glad to say I can be proud of the way my work is being printed.

Sustainable digital printing: opportunities for all designers

By the very nature of digital printing, it is much more sustainable than its prior analogue counterpart which uses massive amounts of water, energy, and toxic dyestuffs to create massive inventories of products. On top of that, a large percentage of this inventory sometimes remains unsold and is difficult (if not impossible!) to dispose of.

In the relatively new Sell/Produce/Deliver model (a term I believe was coined by Debbie McKeegan), the item is purchased first from an online venue like Redbubble,Spoonflower or Society6.e The customer prepays and the item is literally made to order – there is no making up of anything that hasn’t been presold. There is an inventory of the "white goods" but not the giant number or pre-printed apparel and home décor items of the traditional model. This model is also fast and efficient, fantastically the turnaround from sale-to-delivery of items is usually between 4 to 10 days. Although it could be called "fast fashion", it does considerably cut down on a number of the problems we have seen with the fast fashion model we have right now.

Print on demand is a fantastic way for me, as an old school surface designer, to create items virtually to sell online via this relatively new Sell/Produce/Deliver model. I am over the moon as I get to do my business this way, especially since I see more and more selling platforms and items coming online regularly. As a designer, I consider myself to be a very lucky part of this sustainable Fashion Revolution. All I need is the investment of my time and talents to open an online shop at an established print-on-demand website.

The process: from design to sustainable digital printing

It is such a contrast to the clunky slow process that was the fashion in the 80s and 90s when I worked as both, a silhouette and textile designer in NY, for a large bodywear company. And as someone who has experienced the giant fashion industry machine first hand, my heart is gladdened by the brighter future digital printing and POD affords to everyone - whether you are a small or large company.

This new paradigm of digital printing on demand has created lots of small companies that sell through venues like Etsy where you can print your own fabric by the yard through Spoonflower, then make garments, toys, pillows (as you wish) at home and open your Etsy online shop.

The possibilities are limitless once you realize how easy this is to do! And also how affordable it is compared to the analogue model: you no longer have to purchase 10,000 yards of fabric in one design. In fact, you can just buy a fat quarter that is 18” x 21” to do a test run of your chosen pattern and create one small item to start your empire. You can also create an apparel or home décor brand via Society6 and Redbubble and you won’t even have to pay for the use of your shop!

Sustainable Digital printing vs Analogue printing

For me personally, digital printing has been a dream come true. The previous manner of analogue printing, designers had to separate the colours into a disappointingly small number of screens. Not a good way for my work to be translated onto fabrics or wallpaper because my designs are originated by hand in watercolours on paper.

Instead, the advent of digital printing means that my work, in all it’s subtleties, nuances and colour saturation, is perfectly rendered via the auspices of digital printing. The prior way to really achieve the look of my work was also prohibitively expensive, because of the large investment required to create Galvano screens and large inventories to make a run worth undertaking.

All I need for my work is paintbrushes, watercolours, a scanner and Photoshop, to create my pattern repeats, and have the work ready for online upload. Creating the pattern for repeat and placement prints and is ready for sale in my multiple online prints on demand shops. Basically, it's just a matter of hours or days as the shops provide all you need to render your items virtually and ready for sale.

Then the POD companies take care of everything else when a sale is made, and I make the equivalent of royalty as profit – for me, it’s the perfect model – and I can do it from anywhere that has a good internet connection!

What more could you want as a surface designer? The only hard part, as with any business, is the marketing and getting customers to my shops.

I jumped aboard the POD bandwagon the very second I realized what a perfect vehicle it was for my artwork and textile patterning and wow these companies started to spring up all over the world – in the US, Canada, Australia, the UK. Today, I can sell my items to anyone anywhere!

Nowadays, I am combining analogue and digital to my heart’s content and I only see the future looking brighter and brighter for my chosen career model, especially so as companies like Doc Cotton (Peckham, London) are improving on the current model by offering all their clothes in 100% sustainable and or organic cotton. It is a great move away from so much polyester, which admittedly prints really well but isn’t good for the environment in a number of ways.

My own brand is in the ether, and solely in the ether, until a customer purchases from one of my online shops. From that moment, as if by magic, the POD machinery cranks into work, creates the item ordered and ships it to the customer. Best thing is that my part in the process was already done with the upload of the pattern or placement print.

It truly is my dream come true!

Are you also a designer and just realised about this brighter future with digital printing? Ask any questions and share your insights with me, we are here to support each other ;)

Here's a list of my online shops:

Thank you for reading! Please be in touch via the message box in the right hand column or by comment here - I look forward to hearing from you.

Most appreciatively, Patricia SheaDesigns